Page 6 - Demo

P. 6

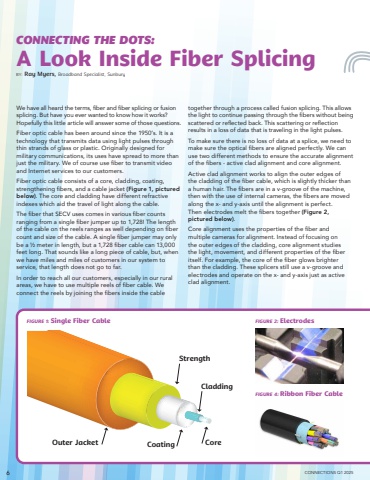

6 CONNECTIONS Q1 2025CONNECTING THE DOTS: A Look Inside Fiber SplicingBY: Ray Myers, Broadband Specialist, SunburyWe have all heard the terms, fiber and fiber splicing or fusion splicing. But have you ever wanted to know how it works? Hopefully this little article will answer some of those questions.Fiber optic cable has been around since the 1950%u2019s. It is a technology that transmits data using light pulses through thin strands of glass or plastic. Originally designed for military communications, its uses have spread to more than just the military. We of course use fiber to transmit video and Internet services to our customers. Fiber optic cable consists of a core, cladding, coating, strengthening fibers, and a cable jacket (Figure 1, pictured below). The core and cladding have different refractive indexes which aid the travel of light along the cable. The fiber that SECV uses comes in various fiber counts ranging from a single fiber jumper up to 1,728! The length of the cable on the reels ranges as well depending on fiber count and size of the cable. A single fiber jumper may only be a %u00bd meter in length, but a 1,728 fiber cable can 13,000 feet long. That sounds like a long piece of cable, but, when we have miles and miles of customers in our system to service, that length does not go to far. In order to reach all our customers, especially in our rural areas, we have to use multiple reels of fiber cable. We connect the reels by joining the fibers inside the cable together through a process called fusion splicing. This allows the light to continue passing through the fibers without being scattered or reflected back. This scattering or reflection results in a loss of data that is traveling in the light pulses.To make sure there is no loss of data at a splice, we need to make sure the optical fibers are aligned perfectly. We can use two different methods to ensure the accurate alignment of the fibers - active clad alignment and core alignment. Active clad alignment works to align the outer edges of the cladding of the fiber cable, which is slightly thicker than a human hair. The fibers are in a v-groove of the machine, then with the use of internal cameras, the fibers are moved along the x- and y-axis until the alignment is perfect. Then electrodes melt the fibers together (Figure 2, pictured below).Core alignment uses the properties of the fiber and multiple cameras for alignment. Instead of focusing on the outer edges of the cladding, core alignment studies the light, movement, and different properties of the fiber itself. For example, the core of the fiber glows brighter than the cladding. These splicers still use a v-groove and electrodes and operate on the x- and y-axis just as active clad alignment.Outer Jacket CoatingStrengthCladdingCoreFIGURE 1: Single Fiber Cable FIGURE 2: ElectrodesFIGURE 4: Ribbon Fiber Cable